Every customer of R & H Machine has his own wear story. Thousands of farmers have seen for

themselves the advantages of using Chrome Alloy wear parts. Each farmer's soil is different with

varying degrees of abrasion, but all have seen a reduction in wear when using our parts. Below

are just a few examples of the results that some of our customers have seen when running our

parts on their equipment.

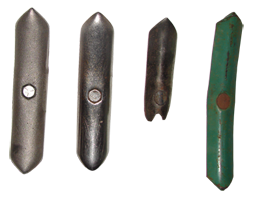

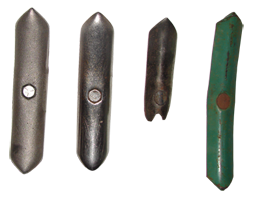

R & H Chrome Alloy

4,000 Acres

600 Acres

Acre for Acre

The examples above were run on two Southwest Idaho farms, and show the comparison between

standard steel S-tine points and our Chrome Alloy points. The parts on the left show a new R & H

Chrome Alloy point and one that has run 4,000 acres. The parts on the right ran 600 acres in a

one-to-one comparison between standard steel and R & H Chrome Alloy points. Also shown are

the new parts to the outside of each worn point. You can see the much longer life of the R & H

Chrome Alloy point, as it eventually outwore 44 of the steel parts without changing the bolt.

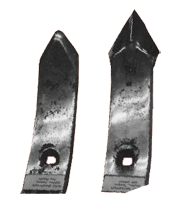

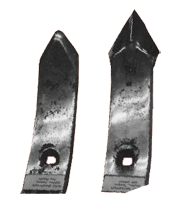

R & H Chrome Alloy

Standard

Run side by side for thirty days -- Warden, Washington

The potato-digger parts shown above ran for thirty days at Warden, Washington. The standard

cone shows a deep groove cut by the chain, while the R & H Chrome Alloy cone is merely

polished where the chain ran over it.

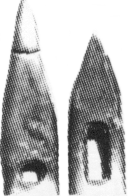

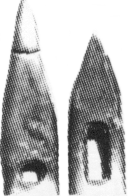

Standard / R & H

Acre for Acre

R & H / Standard

Acre for Acre

The examples above show two sets of chisel points run side-by-side and acre-for-acre. The ones

on the left side were run at Condon, Oregon; the ones on the right were run at Arbuckle, California.

In both areas the soil was extremely abrasive.

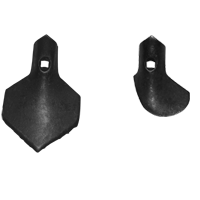

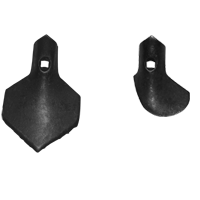

Standard

R & H Chrome Alloy

The four-inch incorporating shovels shown above are before and after photos of a standard hardfaced

shovel and R & H Chrome Alloy run side by side in Hanford, California. The standard

hardfaced shovel was completely worn out after 150 acres. The R & H Chrome Alloy shovel was

polished, but still the original size after 2,500 acres. The standard shovel would have had to be

replaced 17 times.

WHICH ONE IS MORE EXPENSIVE?

If you have the time to replace worn parts ~ ~ ~

you have the time to figure your savings!